LASER MACHINE SOFTWARE USER INTERFACE

SELECT TOOL

In the select tool, you select all, deselect.

Select a similar curve. (Mostly used)

Select outer mould.

Select inner mould.

Select the layer.

SELECTION OF GRAPHICS BY MOUSE

If you left-click of mouse and drag left to right the graphics come under this is selected.

If you left-click of mouse and drag right to the left small entity is needed to select the whole entity.

TECHNICAL PARAMETERS

The technical tool is used in cutting to get a good finish and accurate size.

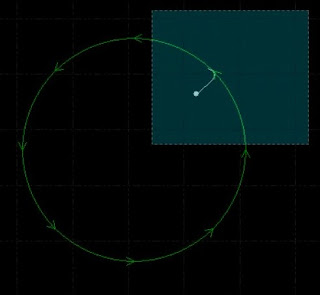

LEAD POSITION

It is used to position the lead according to you.

COMPENSATE

It used to get an accurate size by compensating the entities.

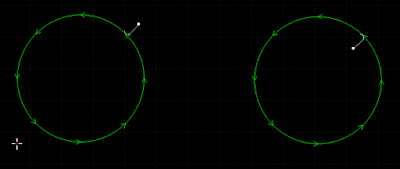

OUTER AND INNER

It is used to position lead inner and outer.

MICROJOINT

It is used to create micro joint so that cut pieces do not collapse with the head of Laser.

FILLET

It is used to remover sharp edges by providing them radius.

RELEASE

It is provided at the corner by providing a radius outside.

COOLING POINT

It is the technical parameter to get a smooth edge while cutting. It for stops head sometimes at the cooling point and then start cutting.

TOOLS

The array is used for copying the objects in RECTANGULAR & CIRCULAR PATTERN.

RECTANGULAR ARRAY is used copying objects is a rectangular pattern. In this, we need to specify rows and columns. Distance is also needed to specify.

Step 1. Select the graphics.

Step 2. Click on the array and select a rectangular array.

Step 3. Give the number of rows and columns and distance

Step 4. click ok.

Comments

Post a Comment