BRIEF OF MECHANICAL PARTS

The LASER cutting machine mainly consists of seven parts

1. HOST

2. OPERATIONAL PLATFORM

3. ELECTRICAL CONTROL SYSTEM

4. EXHAUST SYSTEM

4. EXHAUST SYSTEM

5. GASWAY SYSTEM

6. WATER CHILLING UNIT

7. OPTICAL PATH SYSTEM

1. HOST

The host important part of the entire equipment. The cutting function and precision are realized by the host.

1.1 MACHINE BODY

The mainframe of the machine body. It is the main structure of the machine. In every system, the first of the structure is prepared. In Laser cutting machine the structure performs the different function. It absorbs the vibration. The number of parts is mounted on the structure. The structure is made of carbon structural steel. It involves a process like stress annealing and vibrating ageing treatment.

1.2 BEAM

The beam of the laser machine is the third generation cast aluminium beams to adopt heavy steel mould casting. The beam consists of a rack and pinion arrangement which helps the machine to move forward and backwards.

1.3 BED

The bed of the laser machine is stationary on workpiece (sheet or plate) rest. The cutting head of the laser is moved to get the desired shape. The size of the bed is mainly 1500mm x 3000mm for low space. Where space is large the size of the bed is 15000 mm x 6000mm. The workbench is exchanging

2. OPERATIONAL PLATFORM

The operational platform is the control Centre of equipment. The operator controls the machine with the use of the software.

3. ELECTRICAL CONTROL

The control panel is a metal box which contains important electrical equipment's that control and monitor mechanical process electrically.

The control panel consists of:

- ENCLOSURE

- MOUNTING

- DIN RAILS (USED TO MOUNT ELECTRICAL DEVICES)

- WIRING DUCT

- MAIN CIRCUIT BREAKER

- TRANSFORMER

- PLC

- HMI

- DRIVE ETC.

4. EXHAUST SYSTEM

The exhaust is used to remove dust and harmful gases from the machine in working condition.

There is a pipeline through which the gases and dust are removed. The exhaust system is provided to remove gases and also provide a safe working environment.

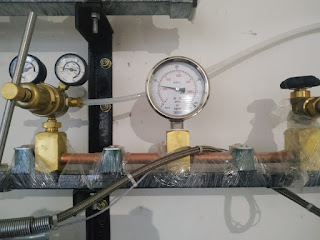

5. GASWAY SYSTEM

The gasway system is used as cutting gas. Oxygen and Nitrogen can be connected simultaneously. Oxygen and Nitrogen are the cutting gas in laser fibre cutting. The pressure of gases can be automatically regulated.

The oxygen cylinder is painted black.

The nitrogen cylinder is painted blue.

The gasway system is provided with pressure gauges, connected pipe, nozzle. The pressure is regulated according to the thickness of metal to be cut.

oxygen is used for cutting mild steel.

nitrogen is used for cutting stainless steel, galvanized iron, aluminium etc.

6. WATER CHILLING UNIT

The chiller unit is used for cooling the laser generator (source). The low-temperature water is used for cooling is cooling laser and high-temperature water is used for cooling the laser head. The chilling circuit is simple and as shown in fig. The temperature of the chilling unit is to maintain 24*C to 28*C.

7. OPTICAL PATH SYSTEM

The optical path system is composed of the fibre laser and cutting head.

7.1 FIBER LASER

It consists of a tube filled with an atom that is an active medium. When the energy is given to atom they became excited. Two reflecting mirror at the end of tube confine photons to the tube. One of the mirrors is reflecting. Another mirror is made transparent. A transparent mirror allows the laser to escape.

7.2 CUTTING HEAD

The cutting head mainly includes cavity, collimating lens, focusing lens base, focusing mirror, upper and lower protective lens, capacitive sensor auxiliary gas, nozzle etc. The cutting is moved to get the desired shape. The servo motor is used to move the head up and down.

OPTICAL PATH ASSEMBLY

5. GASWAY SYSTEM

The gasway system is used as cutting gas. Oxygen and Nitrogen can be connected simultaneously. Oxygen and Nitrogen are the cutting gas in laser fibre cutting. The pressure of gases can be automatically regulated.

The oxygen cylinder is painted black.

The nitrogen cylinder is painted blue.

The gasway system is provided with pressure gauges, connected pipe, nozzle. The pressure is regulated according to the thickness of metal to be cut.

oxygen is used for cutting mild steel.

nitrogen is used for cutting stainless steel, galvanized iron, aluminium etc.

6. WATER CHILLING UNIT

The chiller unit is used for cooling the laser generator (source). The low-temperature water is used for cooling is cooling laser and high-temperature water is used for cooling the laser head. The chilling circuit is simple and as shown in fig. The temperature of the chilling unit is to maintain 24*C to 28*C.

7. OPTICAL PATH SYSTEM

The optical path system is composed of the fibre laser and cutting head.

7.1 FIBER LASER

It consists of a tube filled with an atom that is an active medium. When the energy is given to atom they became excited. Two reflecting mirror at the end of tube confine photons to the tube. One of the mirrors is reflecting. Another mirror is made transparent. A transparent mirror allows the laser to escape.

7.2 CUTTING HEAD

OPTICAL PATH ASSEMBLY

for sheet metal post

Comments

Post a Comment